News

Enhancing Supply Chain Transparency through Blockchain Technology

09/07/2024

In a seminal white paper published in November 2008, Satoshi Nakamoto introduced Bitcoin as the pioneering electronic payment system leveraging a decentralized peer-to-peer network, a breakthrough eliminating the necessity for a trusted intermediary. Central to this innovation was the integration of blockchain technology, widely recognized as a milestone in fault-tolerant distributed computing. At its core, blockchain functions as a database encompassing all transactions executed within the peer-to-peer network. This database forms a permanent, distributed digital ledger, inherently resistant to tampering and maintained collectively by all participating nodes.

Blockchain’s unique value lies in its open network, where participants can interact without needing to know or trust each other. Electronic transactions are automatically verified and recorded by network nodes through cryptographic algorithms, eliminating the need for human intervention, central authority, control points, or third-party institutions such as governments, banks, or financial organizations. This decentralized nature is a compelling advantage, one that represents a paradigm shift from relying on human trust to mathematical trust, and thus inviting a broadening of its applicability far beyond the creation of decentralized digital currencies.

And undeniably, these hallmark attributes of traceability and transparency are proving to be profoundly transformative, reshaping traditional paradigms and methodologies. In supply chain management, such shifts are evident in ambitious research initiatives, with industry leaders like Walmart exploring blockchain for tracking pork products from China with a farm-to-table approach, and Carrefour implementing it in organic food traceability campaigns. These initiatives underscore Blockchain's potential to revolutionize supply chain operations, enhancing efficiency, reliability, and consumer trust.

A Current Supply chain Status on Transparency and Traceability

Indeed, supply chain transparency emerges as a critical focus area, gaining traction in recent years. Defined as the extent to which information regarding supply operations, product origins, and cost analyses is voluntarily disclosed to stakeholders within or beyond the supply chain, supply chain transparency has grown to become a fundamental aspect in general supply chain operations, consequently inviting the interest of numerous stakeholders including suppliers, manufacturers, distributors, retailers, governments, NGOs, and customers. Some common examples exemplifying need-transparency include buyers in supply chains advocating for enhanced supply chain visibility through increased access to information and as such empowering them to make informed decisions on crucial matters such as promoting Environmental, Social, and Governance (ESG) criteria and ensuring ethical sourcing practices are upheld.

This example illustrates the complexities of today’s business environment, a landscape that is more interconnected than ever before. Global supply chains are now dispersed, prompting a shift towards partnership and platform-based business models. Additionally, there is a rising tide of expectations from consumers, NGOs, and other stakeholders, as well as pressures to maintain profitability, flexibility, safety, and cost-efficiency, to which failure in meeting these demands can lead to disruptive events and significant reputational risks. For instance, food companies across Europe and other major markets are increasingly expected to provide detailed supply chain information related to ingredients, food fraud prevention, animal welfare, and child labor, amidst challenges such as ongoing inflationary pressures. To that end, efforts to navigate these highly complex supply chains effectively and to adapt swiftly to disruptions are crucial.

Central to these efforts is the establishment of transparent supply chains, which entails comprehensive corporate disclosure across various supply chain dimensions. This includes disclosing (i) supplier names involved in product manufacturing (traceability), (ii) sustainability practices of these suppliers, and (iii) purchasing and sourcing strategies of buying firms.

Traditionally, achieving transparency has relied on a range of reporting and disclosure methods employed by private and civil society entities. These include company sustainability reports, certification schemes, and labels. More recently, a proliferation of transparency tools has emerged, encompassing online databases, scorecards, self-disclosure systems, traceability platforms, local monitoring initiatives, and various types of footprint calculators. Yet, these conventional approaches, characterized by centralized traceability solutions, often lead to monopolistic practices, asymmetric information flows, and opaque systems, consequently posing significant challenges for supply chains, including susceptibility to data manipulation, single points of failure, and vulnerabilities to corruption and misinformation. Consequently, businesses fall short of ensuring adequate levels of transparency in their supply chains despite many willing and indeed claiming to prioritise the practice highly. This discrepancy is evident in the findings of a GEODIS Supply Chain Worldwide Survey involving 623 industry professionals across 17 countries. While supply chain visibility ranks among their top priorities, only 6% of surveyed companies claim to have achieved full visibility. This low visibility rate turns to be concerning, especially considering the rising expectations for corporate transparency from stakeholders. Noteworthy too, supply chains were not designed to be transparent, a concern emanating from the fear that divulging too much information would undermine businesses’ competitive advantage or expose them to criticism.

Enhancing Transparency through Blockchain Technology

Blockchain represents an ingenious invention capable of creating transparency and equally serving as a single source of truth for the entire network of supply chain actors. Its application in establishing traceability and transparency across supply chains is increasingly recognized, with widespread adoption in various sectors such as food and agriculture, pharmaceuticals, courier express parcel (CEP) services, and luxury goods.

Driven by the imperative to enhance transparency, private and permissioned parties within these kinds of supply chains both contribute to and access comprehensive information regarding product sourcing, manufacturing, and distribution. Blockchain's immutable ledger securely stores data entered at each stage of the supply chain, enabling all stakeholders—from manufacturers to distributors and retailers—to access a unified, trustworthy source of information. This decentralized nature of blockchain ensures that information remains consistent, accurate, and tamper-proof, fostering trust and collaboration across the entire supply chain network.

Consider an instance in the food industry, a sector where tracing the origin of contaminated products during a recall can be challenging due to intricate supply chain networks. This complexity often results from a lack of transparency and consequently births potential risks, including the spread of unsafe products in the market. However, with blockchain technology implemented, every step of the supply chain becomes traceable and transparent. This end-to-end visibility allows for real-time monitoring of every transaction, movement, and transformation within the supply chain, facilitating seamless coordination and interconnectedness across the supply chain, thereby mitigating risks and enhancing responsiveness during product recalls and other critical events.

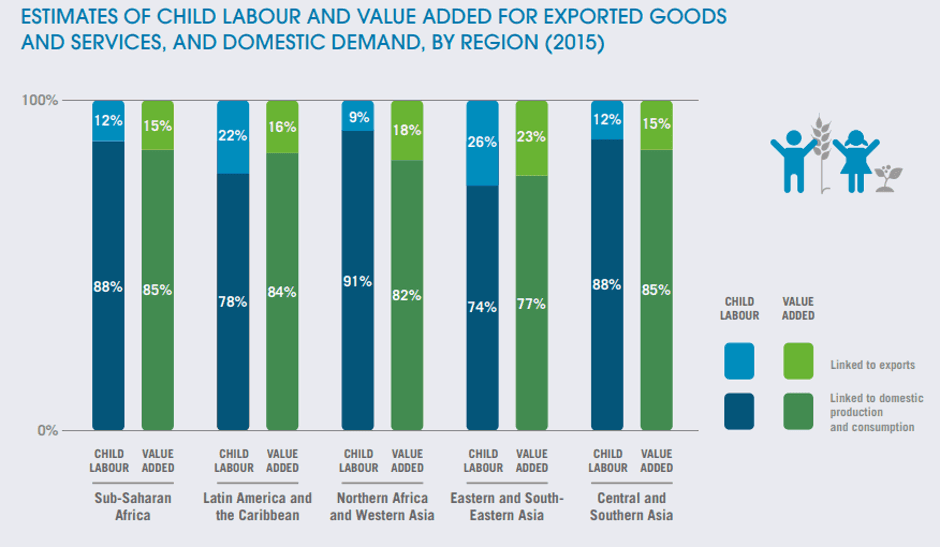

Worth mentioning too is blockchain enhances traceability, a crucial feature given the linear flow of most goods from material origin to the final consumer. This capability allows stakeholders to track a product's journey from its source to the end consumer, ensuring accountability within the supply chain and facilitating the identification of any issues or discrepancies. This is particularly significant against the backdrop of rising regulatory requirements for supply chain transparency, especially concerning child labor. According to the latest global estimates by ILO, 152 million children are engaged in child labor, and 25 million adults and children are in forced labor, including within global supply chains. The challenge is particularly pronounced in upstream segments of the supply chain, such as raw material extraction and agriculture, where abuses are more likely to occur; thus underscoring the need for enhanced visibility and responsible practices throughout the supply chain.

Figure 2 Estimates of Child Labour Across Various Regions Adapted From International Labour Organisation (ILO). (n.d.). Ending Child Labour, Forced Labour and Human Trafficking in Global Supply chains.

With every partner, including businesses, committing to end child labor by 2025 as part of the Sustainable Development Goals (SDGs), robust action against these human rights violations is imperative. Businesses are increasingly integrating measures to mitigate risks related to labor rights violations through human rights impact assessments and transparency initiatives. Blockchain emerges as a promising solution in combating these challenges. Leveraging its decentralized and immutable nature, each stage of the supply chain is assigned a digital code, enabling comprehensive tracking and tracing. Such transparency empowers stakeholders to detect any potential involvement of child labor, a capability that conventional survey and national accounting methods lack. Consequently, businesses can easily demonstrate compliance with industry and governmental regulations, avoiding legal pitfalls and ensuring ethical practices.

A noteworthy example includes prominent companies like Ford Motor Company, LG Chem, and Huayou Cobalt, collaborating to implement blockchain technology in cobalt mining and marketing processes in the Democratic Republic of the Congo (DRC). This innovative blockchain-based platform facilitates monitoring and assessment across every stage of production, from mining in remote Southern Congo—home to the majority of global cobalt reserves—to Asian smelters, refineries, and the global trading market. The platform securely records crucial details such as mine names, mining timestamps, quantities extracted, miner identities, and smelter processing information. This immutable data ensures that Ford, LG Chem, and Huayou Cobalt can trace cobalt throughout the supply chain, ensuring ethical practices including the prevention of issues like child labor.

Another noteworthy example is the use of blockchain traceability applications to track yellowfin and skipjack tuna throughout an entire supply chain. A project, powered by Ethereum and conducted from January to June 2016, allowed end-users to trace the journey of their tuna fish sandwiches using a smartphone. Consumers could access detailed information about producers, suppliers, and processing procedures involved in the final product. Each unit of measure, whether by fish or by catch, was assigned a digital token to verify its origin and track its progress through the supply chain. This initiative demonstrated a practical model for product certification that enhances transparency and accountability for end consumers, leveraging blockchain technology to ensure authenticity and ethical sourcing practices in the seafood industry.

The Drawback

Of course, the adoption of blockchain technology in supply chains is not without its drawbacks. A significant barrier, yet a critical enabler in the adoption of blockchain technology in global supply chains, is the provision and availability of the necessary information to support the required level of transparency. This issue often stems from the compatibility concerns regarding the willingness and capacity—or lack thereof—of supply chain members to share data and cooperate in establishing common process standards, rules for information disclosure, and related supply chain objectives, a move that consequently necessitates changes in internal operational processes to maintain traceability and support the detailed data requirements. Oftentimes, firms hesitate to make needed information visible beyond immediate supply chain partners due to the following dilemma: while increased information availability can enhance operational decision-making, there is concern that participants in the blockchain network could exploit shared information for competitive advantage. Consequently, many current blockchain applications in supply chains either restrict information sharing to direct partners or involve efforts to remove intermediaries from the process, aiming to balance transparency with safeguarding competitive interests.

Other forms of barriers include the high cost of implementation, the need for technological infrastructure, and potential resistance to change from established practices. Nonetheless, the potential benefits of blockchain, such as improved operational decisions, fraud reduction, and enhanced consumer trust, make it a promising solution for modern supply chain management and therefore addressing the above hurdles would be more strategic than prohibitive, paving the way for a more transparent, efficient, and resilient supply chain ecosystem.

APICS' globally-recognized courses provide valuable insights about Supply Chain Design and effective management, including topics such as blockchain and other technologies to increase Supply Chain visibility.

Our expert-led APICS CPIM, (Certified in Planning & Inventory Management), CSCP (Certified Supply Chain Professional) and CTSC (Certified in Transformation for Supply Chain) programs, besides the on-line Technology Certificate will support organizations with any Supply Chain improvement program and help you stay ahead of the curve in this critical area of business operations.

By joining our courses, you'll have the chance to learn from industry leaders, gain in-depth knowledge, and expand your professional network. Additionally, you'll earn globally recognized certifications that showcase your expertise, setting you on the path to a successful career in supply chain management.

Enroll today and take the first step towards optimizing your supply chain strategies and realizing your full potential. Contact Jessica Mariotti for info about our courses, open classes and In-house in Italy and Switzerland, early registration fee and enrolment - Email info@advanceschool.ch - phone numbers under Contacts

Courses linked

-

Master APICS CSCP - Certified Supply Chain Professional - Interactive Live Webinar

The Executive Master CSCP Interactive live webinar is designed to prepare the candidate for the Certified Supply Chain Professional certification (CSCP) of APICS, in the Supply Chain Management area. » -

Master APICS CTSC - Certified in Transformation for Supply Chain

This programme is designed to prepare candidates for APICS CTSC international certification (Certified in Transformation for Supply Chain) » -

Technology Certificate - APICS

Stand out in a competitive job market with the new ASCM Supply Chain Technology Certificate. This certificate gives you an understanding of how to implement the latest technologies in your Supply Chain organization to reduce costs, boost performance and achieve a more sustainable Supply Chain. Explore how blockchain and other emerging technologies can support and improve operations within the Supply Chain industry. » -

Master APICS CPIM - Certified in Planning & Inventory Management - Interactive Live Webinar

The APICS Executive Master Interactive live webinar is designed to prepare the candidate for the international Certification in Planning & Inventory Management (CPIM) of ASCM, the Association for Supply Chain Management. » -

Master APICS CSCP - Certified Supply Chain Professional

Executive Master designed to prepare the candidate for the Certified Supply Chain Professional certification (CSCP) of APICS, in the Supply Chain Management area. » -

Master APICS CPIM - Certified in Planning & Inventory Management

The APICS Executive Master is designed to prepare the candidate for the international Certification in Planning & Inventory Management (CPIM) of ASCM, the Association for Supply Chain Management. »